internet of things 4th industrial revolution

So, what’s up my cool cats and kittens? (Yes, I just referenced Tiger King. We’re starting off strong.). Today we’re talking about the Internet of Things, or IoT for short. Basically, it’s a fancy way of saying that your toaster can talk to your coffee maker and your car can talk to your fridge. Sounds crazy, right? Well, it’s happening right now, in the year 2020, which honestly feels like a sci-fi movie come to life.

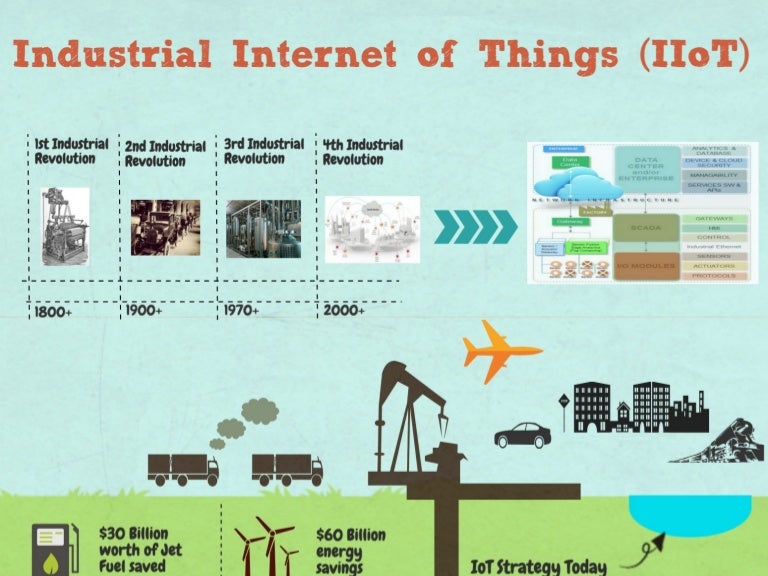

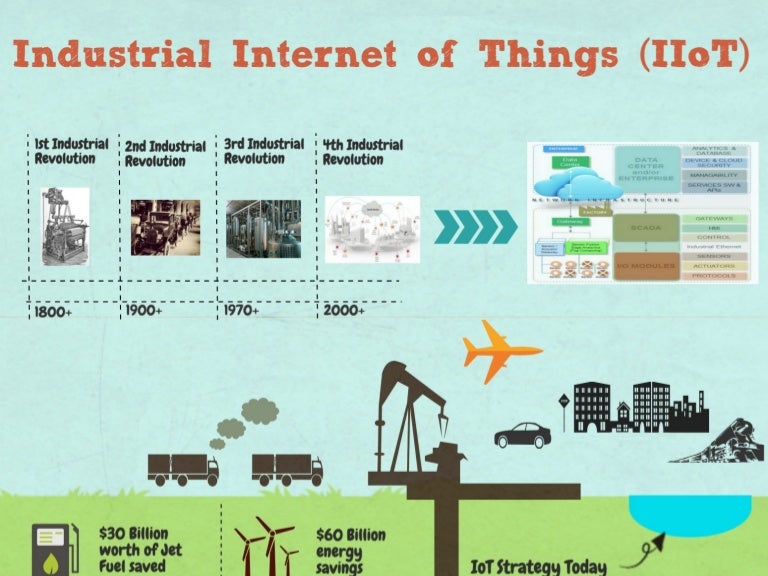

Industrial Internet of Things (IIoT)

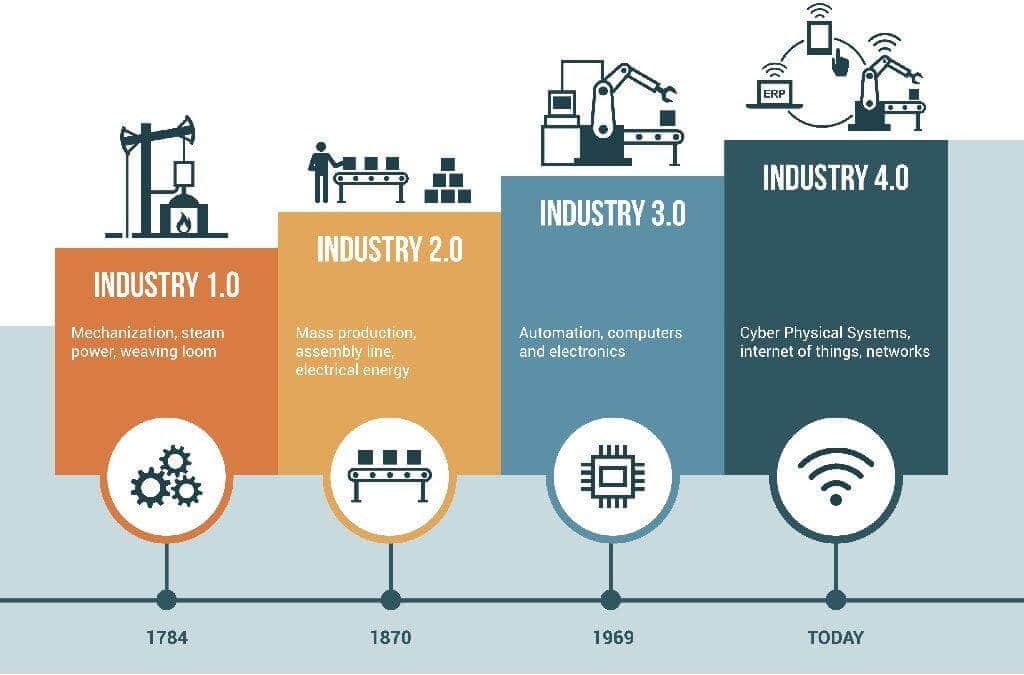

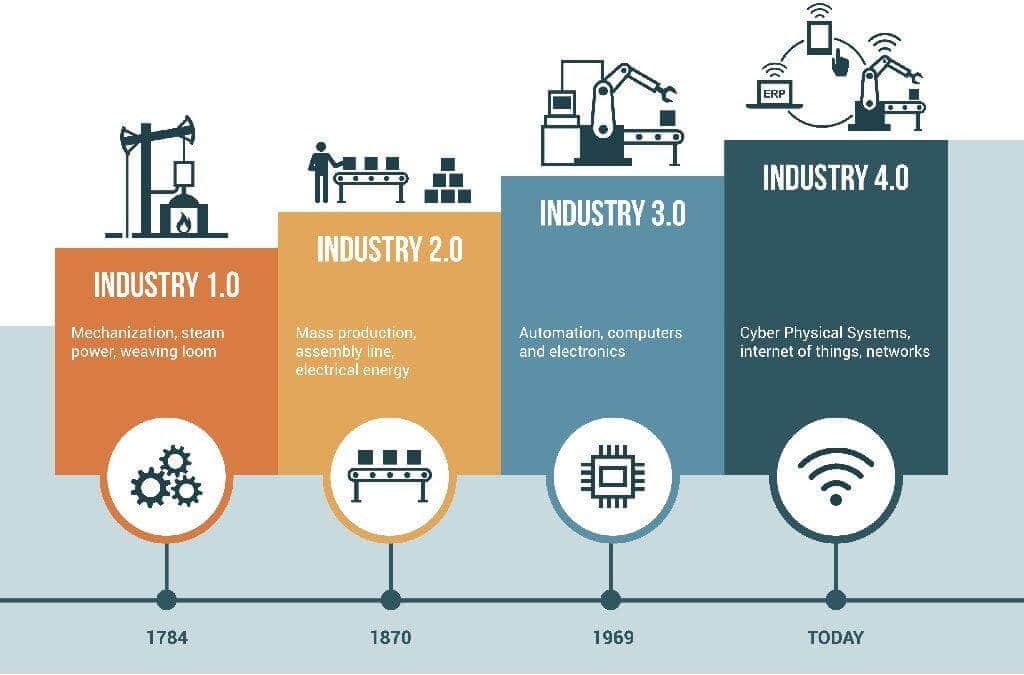

But, hold up. The IoT isn’t just about making our homes more efficient (although, let’s be real, that’s pretty awesome). The Industrial Internet of Things, or IIoT, is revolutionizing the way factories and industries operate. In fact, it’s the fourth industrial revolution. Crazy, right?

Abstract

The IIoT is all about taking advantage of the incredible amount of data that is generated during the production process. By adding sensors and devices to machines and equipment, businesses can collect valuable data that can be used to optimize operations, reduce downtime, and ultimately save money.

Introduction

Okay, let’s back up for a second. What exactly is the IIoT? Basically, it’s the application of IoT technologies to industrial processes. Imagine a manufacturing facility where every machine, conveyor belt, and piece of equipment is connected to the internet. Data is constantly being sent and received, allowing businesses to monitor and analyze every aspect of their operation in real-time.

Content

One example of the IIoT in action is predictive maintenance. By analyzing data from sensors and other devices, businesses can identify when a machine is about to fail before it actually does. This allows for proactive maintenance, which can save a lot of time and money compared to waiting for a breakdown to occur.

Another benefit of the IIoT is increased efficiency. By collecting data on equipment utilization, businesses can identify bottlenecks and inefficiencies in their operation. This allows for targeted improvements that can increase throughput and reduce downtime.

And let’s not forget about safety. By monitoring equipment in real-time, businesses can identify potential safety hazards before they become a problem. This can prevent accidents and ensure the safety of workers and the public.

Conclusion

So, there you have it. The IIoT is revolutionizing the way businesses operate, with the potential to save money, increase efficiency, and improve safety. But, like any new technology, there are challenges to overcome. Business owners and managers need to be prepared to invest in new hardware, software, and training to take advantage of the IIoT. But if done right, the benefits can be significant.

Industrie 4.0

Okay, we’ve talked a lot about the IIoT, but what about Industrie 4.0? Don’t worry, we’ve got you covered.

Abstract

Industrie 4.0 is a German initiative to promote the use of digital technologies in manufacturing. It’s often used interchangeably with the IIoT, although some argue that there are subtle differences between the two.

Introduction

The term Industrie 4.0 was first used in 2011 and has since become a buzzword in the manufacturing industry. It’s all about using digital technologies to create smart factories that are more connected and efficient.

Content

Like the IIoT, Industrie 4.0 is all about collecting and analyzing data to improve efficiency and reduce downtime. But it goes beyond just monitoring machines – it also involves the use of technologies like artificial intelligence, cloud computing, and augmented reality.

One of the key aspects of Industrie 4.0 is the creation of cyber-physical systems, which are essentially machines that are connected to the internet and can communicate with each other. This allows for real-time monitoring and optimization of production processes.

Another important aspect of Industrie 4.0 is the concept of “smart products”. This refers to products that are embedded with sensors and other technologies that allow them to communicate with other products and machines. This can lead to new business models, such as product-as-a-service, where products are sold based on usage rather than ownership.

Conclusion

At the end of the day, Industrie 4.0 and the IIoT are all about using technology to create more connected, efficient, and safe workplaces. By collecting and analyzing data, businesses can identify opportunities for improvement and take action before issues become problems. It’s an exciting time to be involved in technology and manufacturing, and we can’t wait to see where it takes us.

That’s all for now, folks. Thanks for tuning in!

Source image : www.pinterest.com

Source image : bvik.org

Source image : www.slideshare.net