How to Choose the Right 3D Printer for You

#image_title

When it comes to manufacturing, the use of 3D printing has revolutionized the industry. With 3D printing, it’s possible to produce end-use parts and prototypes with accuracy, efficiency, and speed. In this blog post, we will discuss the Fused Filament Fabrication (FFF) process and the benefits of using 3D printing for end-use parts manufacturing.

What is Fused Filament Fabrication?

FFF, also known as Fused Deposition Modeling (FDM), is one of the most popular methods of 3D printing. The process involves the use of melted plastic filaments, which are then extruded to produce the desired shape. The filament is melted and extruded layer-by-layer until the final part is complete. When it comes to 3D printing for end-use parts, FFF has several advantages.

Advantages of Fused Filament Fabrication

1. Cost-Effective

Compared to traditional manufacturing methods, 3D printing using FFF is much more cost-effective. The process eliminates the need for expensive tooling and molds, which significantly lowers production costs. With 3D printing, you only pay for the material used to make the part, making it an excellent choice for small production runs.

2. Customization

With FFF 3D printing, it’s possible to produce custom parts that meet specific requirements. Unlike traditional manufacturing, where customization usually involves additional tooling costs, FFF 3D printing allows you to make changes without incurring any additional costs. This is especially beneficial when it comes to producing unique or complex parts.

3. Fast Turnaround

Producing parts using traditional manufacturing methods usually takes weeks or even months. However, 3D printing with FFF allows you to produce parts much faster. With a 3D printer, you can produce parts in a matter of hours or days, depending on the complexity of the design. This means that you can quickly iterate designs and get your products to market faster.

4. Reduced Waste

One of the biggest advantages of FFF 3D printing is that there is less waste produced during production. Traditional manufacturing methods often result in wasted materials due to mistakes, errors or design changes. With FFF, you only use the amount of material required to create the part, significantly reducing waste.

How 3D Printing is Helping End-Part Production

3D printing has already made a significant impact on manufacturing, and it is only set to increase. With the advantages of FFF 3D printing that we’ve discussed, it’s easy to see why it’s becoming the go-to method for end-use parts manufacturing. Let’s take a look at a few examples of how 3D printing is changing the game in end-part production.

Customized Medical Implants

When people require medical implants, such as bone implants or prosthetics, one of the biggest challenges is creating a product that fits the individual’s unique anatomy. 3D printing with FFF solves this problem by producing customized implants based on the patient’s anatomy. This approach ensures a perfect fit and reduces the risk of post-operative complications.

Automotive Parts

The automotive industry is always looking for faster and more cost-effective ways to produce parts. 3D printing offers a solution to this problem by producing parts on-demand without any additional tooling costs. With FFF 3D printing, parts can be made faster, cheaper, and with greater precision than traditional manufacturing methods.

Aerospace End-Part Production

The aerospace industry is known for its complex and precise parts, many of which cannot be produced using traditional manufacturing methods. 3D printing with FFF has become a go-to method for producing complex parts in aerospace. With 3D printing, it’s possible to produce parts with intricate geometries that would be impossible using traditional methods.

Conclusion

3D printing with FFF is revolutionizing the manufacturing industry, and it’s only set to increase. With fast turnaround times, low production costs, and the ability to produce customized parts, it’s no wonder that 3D printing is becoming the go-to method for end-use parts manufacturing. Whether you’re in the medical, automotive, or aerospace industry, 3D printing is changing the game, and it’s here to stay. So, what are you waiting for? Embrace the power of 3D printing and take your manufacturing capabilities to the next level.

If you are looking for The 3D Printing process. Source: Campbell et al. Could 3D Printing you’ve visit to the right page. We have 9 Images about The 3D Printing process. Source: Campbell et al. Could 3D Printing like 3D-printing process promises highly-bespoke prosthetics | The Engineer, Adam D. Perler | Podiatric Surgeon and also Beginners Lesson 2 – The 3D Printing Process – learnbylayers. Here you go:

The 3D Printing Process. Source: Campbell Et Al. Could 3D Printing

www.researchgate.net

additive

3D-printing Process Promises Highly-bespoke Prosthetics | The Engineer

www.theengineer.co.uk

multimaterial prosthetics sakuu nottingham dispositivi fabbaloo

What Is 3D Printing And How 3D Printing Works?

www.jtproto.com

slicing modeling

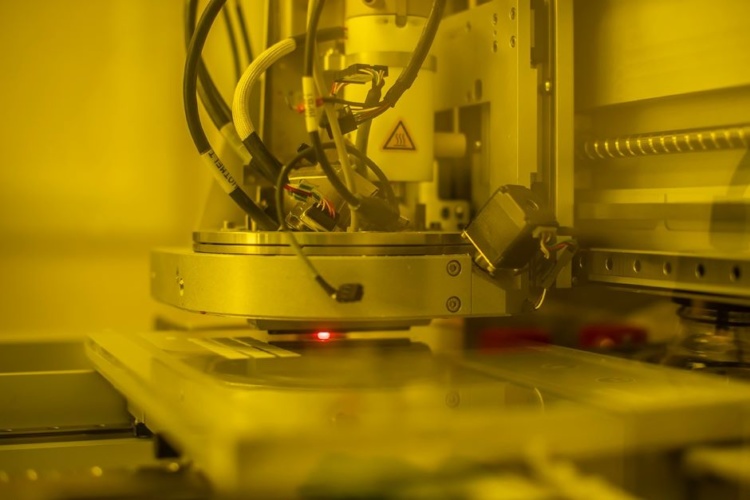

Application Spotlight: 3D Printing For End-Part Production – AMFG

amfg.ai

dmls amfg

The Road Ahead For 3D Printers – IStart Keeping Business Informed On

istart.com.au

3d printing printers ahead road istart technology

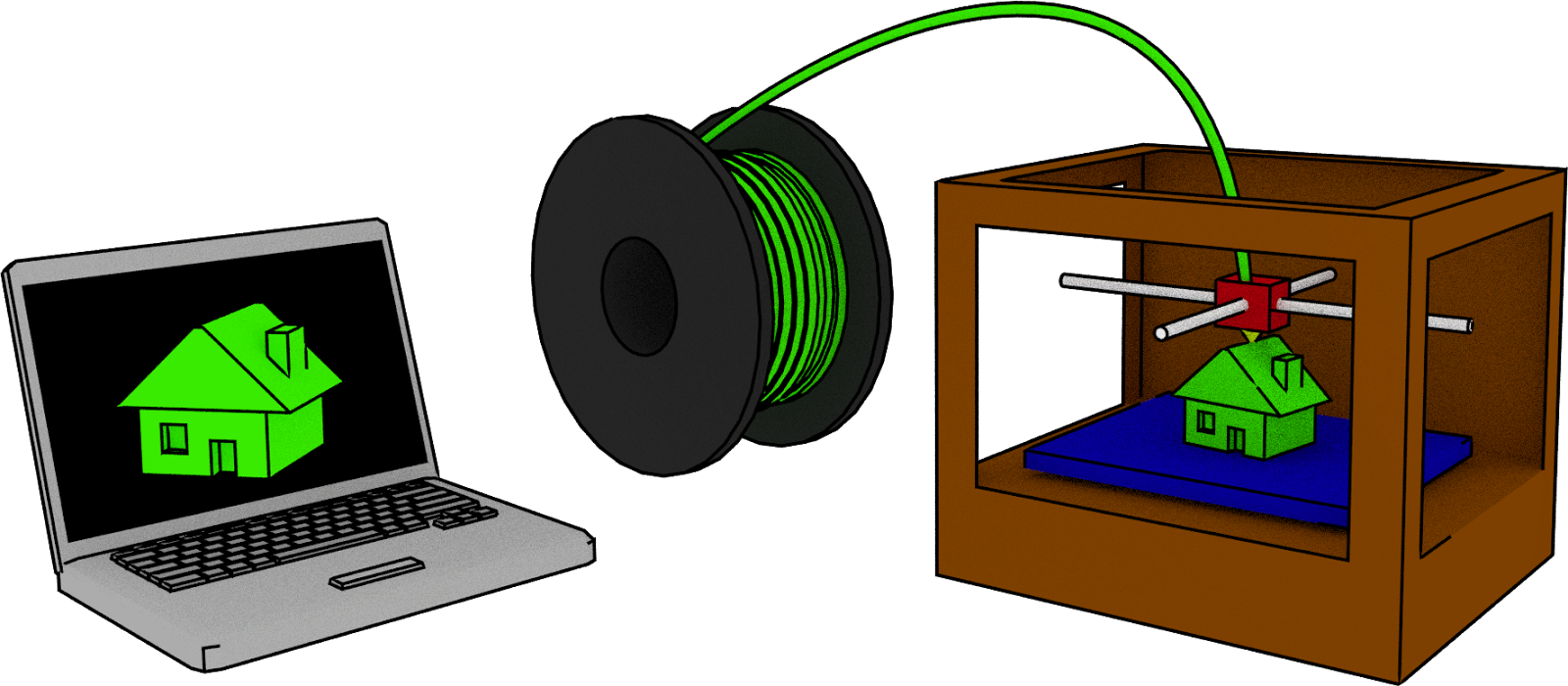

Beginners Lesson 2 – The 3D Printing Process – Learnbylayers

www.learnbylayers.com

3d printing process printer print introduction beginners lesson graphic learn computer work

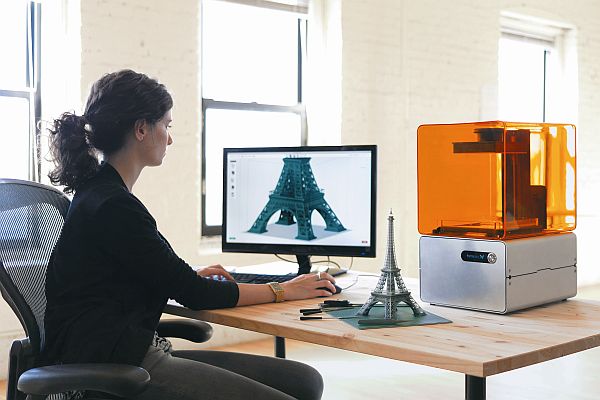

3D Printing 101 – The FFF Process – 3D Printing Professor

www.3dpprofessor.com

3d process fff printing

3D Printing Process

www.pinterest.co.uk

printers papan howto3dprint

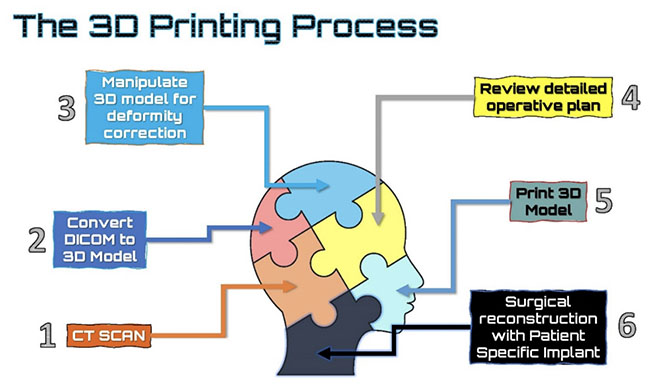

Adam D. Perler | Podiatric Surgeon

www.adamperler.com

3d printing process patient identification starts sent application then right

3d process fff printing. The 3d printing process. source: campbell et al. could 3d printing. Printers papan howto3dprint