edge computing for manufacturing

Edge computing is revolutionizing the way that smart manufacturing operates. With the ability to process data at the edge, manufacturers are now able to improve productivity and reduce costs like never before. Here are two images that illustrate the key drivers and benefits of edge computing in smart manufacturing.

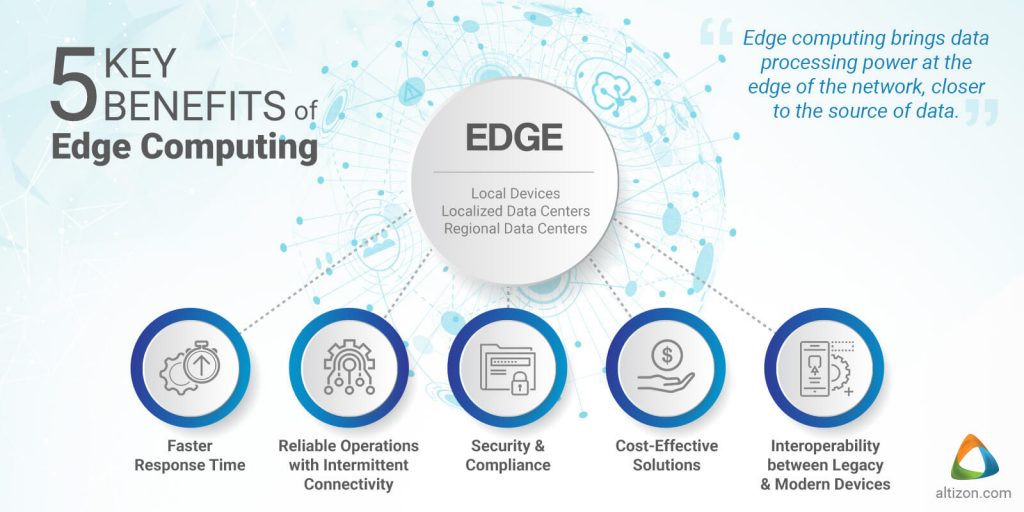

Drivers of Edge Computing for Smart Manufacturing

Abstract

Smart manufacturing is all about improving efficiency, reducing costs, and increasing productivity. It’s a process that requires a lot of data – and the ability to process that data quickly and accurately. This is where edge computing comes in. By moving some of the data processing to the edge, manufacturers can reduce latency, improve data security, and create a more resilient system.

Introduction

In the past, smart manufacturing relied on centralized computing resources, with all data being sent to the cloud or to on-site servers for processing. However, this model has its limitations. Latency can be an issue, particularly when dealing with large amounts of data, and the security of the data can be compromised if it is being transmitted over a network.

Edge computing solves these issues by processing data at the edge of the network, closer to the source of the data. This means that data is processed faster, reducing latency and allowing for real-time decision making. Additionally, because the data is not being transmitted over a network, it is more secure.

Body

So, how does edge computing work in the context of smart manufacturing?

1. Reduced Latency

One of the key benefits of edge computing is the reduced latency that it provides. By processing data closer to the source, edge computing can help to minimize the time it takes for data to be processed and for actions to be taken based on that data. This is particularly important in smart manufacturing, where decisions need to be made in real time.

For example, consider a manufacturing plant where sensors are used to monitor the production process. Without edge computing, these sensors might send data to a central server for processing. This could result in a delay between the time that the sensor detects an issue and the time that the issue is detected by the server. With edge computing, however, the data can be processed locally, allowing for real-time detection of any issues.

2. Increased Data Security

Another advantage of edge computing is the increased data security that it provides. When data is transmitted over a network, there is always the risk of interception or hacking. With edge computing, however, the data is processed locally, reducing the need for data to be transmitted over a network. This means that the data is more secure, as it is not exposed to the same risks that it would be when transmitted over a network.

3. Improved Resiliency

Edge computing can also help to improve the resiliency of smart manufacturing systems. By processing data locally, manufacturers can ensure that their systems are able to operate even if the central server goes down. This means that the manufacturing process can continue uninterrupted, reducing downtime and increasing productivity.

4. Real-Time Decision Making

Perhaps the most significant benefit of edge computing in smart manufacturing is the ability to make real-time decisions based on data. With edge computing, data can be processed as it is generated, allowing for immediate actions to be taken based on that data. This could include adjusting production processes to optimize efficiency, detecting and responding to equipment failures before they cause downtime, and much more.

Overall, edge computing is a game changer for smart manufacturing. By moving data processing to the edge, manufacturers can improve productivity, reduce costs, and create a more resilient and secure system.

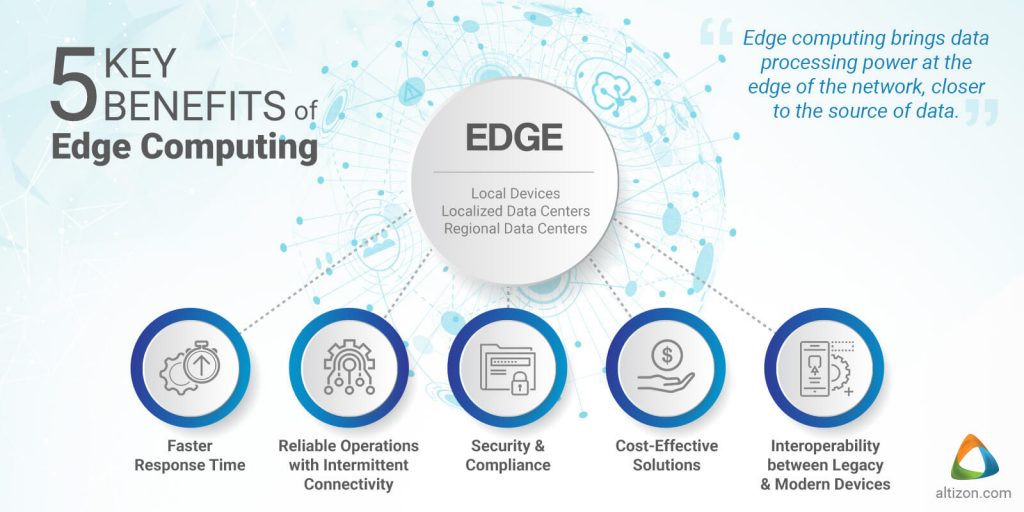

Benefits of Edge Computing for Smart Manufacturing

Abstract

Edge computing is rapidly becoming a key element in the evolution of smart manufacturing. By moving data processing to the edge of the network, manufacturers are able to improve production efficiency, reduce operational costs, and enhance their decision-making capabilities. This diagram illustrates some of the key benefits of edge computing in smart manufacturing.

Introduction

Smart manufacturing is a data-intensive process that relies on the ability to process large amounts of data quickly and accurately. Traditional computing models, where all data is sent to a central server or the cloud for processing, can be slow and inefficient. Edge computing solves this problem by processing data locally, at the edge of the network, where it is generated.

This leads to a range of benefits for smart manufacturing, including increased efficiency, reduced downtime, and enhanced decision-making capabilities. This diagram illustrates some of the key benefits of edge computing for manufacturers.

Body

So, what are the key benefits of edge computing in smart manufacturing?

1. Increased Efficiency

One of the primary benefits of edge computing is the increased efficiency that it provides. By processing data locally, manufacturers are able to reduce latency and improve real-time decision-making capabilities. This can lead to more efficient production processes and a reduction in operational costs.

2. Reduced Downtime

Edge computing can also help to reduce downtime in smart manufacturing systems. By processing data locally, manufacturers can detect and respond to equipment failures and other issues more quickly. This means that downtime can be minimized or even eliminated, leading to increased productivity and reduced costs.

3. Enhanced Decision-Making Capabilities

Edge computing also allows for enhanced decision-making capabilities in smart manufacturing. By processing data locally, manufacturers can analyze data in real time, allowing for faster and more accurate decision making. This means that manufacturers can respond more quickly to changing conditions and optimize their production processes for maximum efficiency.

4. Improved Data Security

Because edge computing processes data locally, it is also more secure than traditional computing models. Data is not transmitted over a network, reducing the risk of interception or hacking. This means that manufacturers can be confident that their data is safe and secure.

5. Greater Flexibility

Finally, edge computing provides greater flexibility for smart manufacturing systems. Because data processing is distributed across the network, manufacturers can build systems that are more adaptable and responsive to changing conditions. This means that manufacturers can optimize their production processes for maximum efficiency, reducing costs and improving overall performance.

Conclusion

Edge computing is transforming smart manufacturing, providing manufacturers with the ability to process data more efficiently, reduce downtime, and enhance overall productivity. By moving data processing to the edge of the network, manufacturers can take advantage of real-time decision-making capabilities and optimize their production processes for maximum efficiency. With its range of benefits, edge computing is set to become a key element in the evolution of smart manufacturing.

Source image : altizon.com

Source image : www.controleng.com

Source image : sfmagazine.com