4 steps to successful edge computing deployments

#image_title

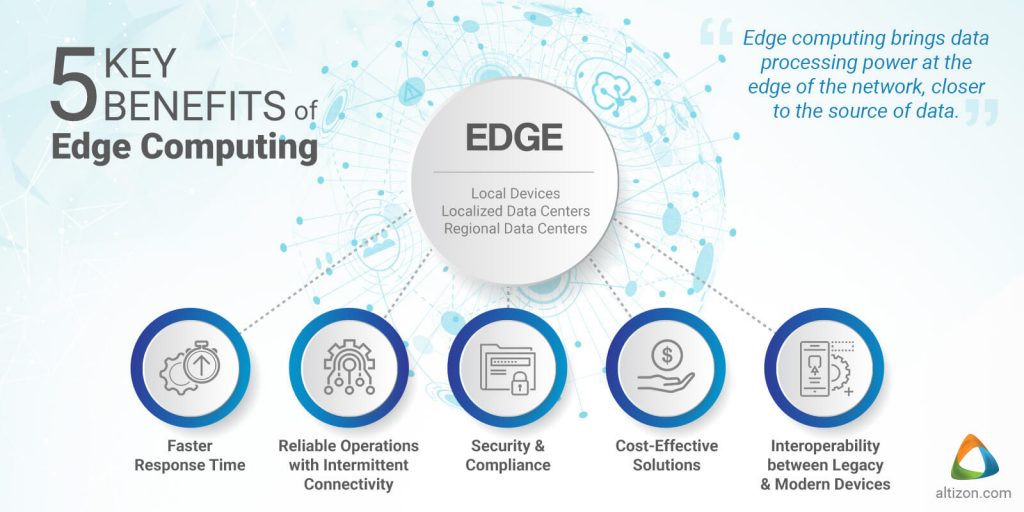

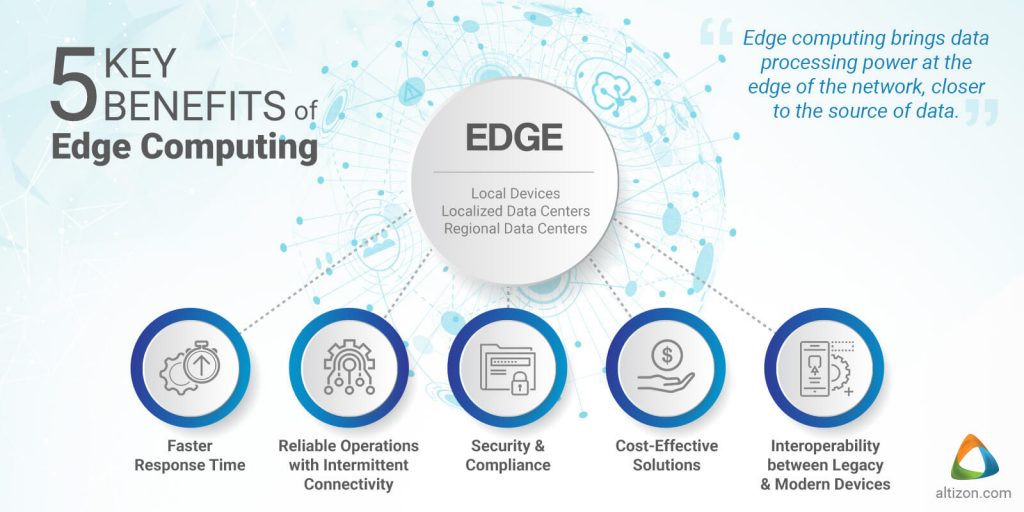

Emerging technologies are changing the way we think about computing. Nowhere is this more evident than in the field of edge computing. By bringing compute and analytics closer to where data is generated, edge computing is improving performance, scalability, and data privacy for a variety of applications.

Rugged Edge Computing: Improving Performance in Harsh Environments

One of the biggest challenges in edge computing is providing reliable computing resources in harsh or remote environments. This is where rugged edge computing comes in. Rugged edge computing platforms are designed to withstand extreme temperatures, shock, vibration, and other environmental stresses.

Rugged edge computing is particularly useful in industries such as oil and gas, mining, and military where computing resources must operate in extreme conditions. With rugged edge computing, these industries can benefit from the performance improvements and cost-savings of edge computing without having to worry about reliability.

Edge Computing for Smart Manufacturing: Improving Efficiency and Quality

Another area where edge computing is making a big impact is in smart manufacturing. By bringing compute and analytics closer to the production line, edge computing is improving efficiency, quality, and productivity in a variety of ways.

For example, edge computing can enable predictive maintenance by continuously monitoring and analyzing equipment data in real-time. By predicting equipment failures before they occur, edge computing can save manufacturers time and money by avoiding downtime and reduce inventory costs by cutting down on the number of spare parts needed.

Abstract

Emerging technologies are changing the way we think about computing. Nowhere is this more evident than in the field of edge computing. By bringing compute and analytics closer to where data is generated, edge computing is improving performance, scalability, and data privacy for a variety of applications.

One of the biggest challenges in edge computing is providing reliable computing resources in harsh or remote environments. This is where rugged edge computing comes in. Rugged edge computing platforms are designed to withstand extreme temperatures, shock, vibration, and other environmental stresses. With rugged edge computing, industries such as oil and gas, mining, and military can benefit from the performance improvements and cost-savings of edge computing without having to worry about reliability.

Another area where edge computing is making a big impact is in smart manufacturing. By bringing compute and analytics closer to the production line, edge computing is improving efficiency, quality, and productivity in a variety of ways. For example, edge computing can enable predictive maintenance by continuously monitoring and analyzing equipment data in real-time. By predicting equipment failures before they occur, edge computing can save manufacturers time and money by avoiding downtime and reduce inventory costs by cutting down on the number of spare parts needed.

Introduction

In recent years, the rise of the Internet of Things (IoT), artificial intelligence (AI), and other emerging technologies has driven the need for new approaches to computing. One of the most promising of these approaches is edge computing. By bringing compute and analytics closer to where data is generated, edge computing offers numerous benefits over traditional cloud computing, including improved performance, scalability, and data privacy.

However, edge computing is not without its challenges. One of the biggest of these challenges is providing reliable computing resources in harsh or remote environments. This is where rugged edge computing comes in. By providing computing resources that can withstand extreme temperatures, shock, vibration, and other environmental stresses, rugged edge computing makes it possible to use edge computing in a variety of industries where traditional computing resources would fail.

Another area where edge computing is making a big impact is in smart manufacturing. By bringing compute and analytics closer to the production line, edge computing is improving efficiency, quality, and productivity in a variety of ways. For example, edge computing can enable predictive maintenance by continuously monitoring and analyzing equipment data in real-time. By predicting equipment failures before they occur, edge computing can save manufacturers time and money by avoiding downtime and reduce inventory costs by cutting down on the number of spare parts needed.

Content

Rugged edge computing is particularly well-suited for use in industries such as oil and gas, mining, and military where computing resources must operate in harsh or remote environments. Traditional computing resources would be unable to operate in these environments due to temperature fluctuations, high levels of dust and debris, and other environmental stresses.

By providing computing resources that can withstand these conditions, rugged edge computing allows for the deployment of edge computing systems in these industries. This, in turn, enables the use of edge computing benefits such as improved performance, scalability, and data privacy in these industries.

One example of how rugged edge computing is being used is in the oil and gas industry. With rugged edge computing, oil and gas companies can collect and analyze data from remote drilling sites in real-time, improving drilling productivity and safety. By monitoring drilling equipment in real-time, companies can identify potential problems before they occur, avoiding costly downtime and improving worker safety.

Another example of how rugged edge computing is being used is in the mining industry. With rugged edge computing, mining companies can collect and analyze data from mines in real-time, improving efficiency and safety. By monitoring equipment and environmental data in real-time, companies can optimize their mining processes and avoid equipment failures, reducing maintenance costs and increasing worker safety.

Finally, rugged edge computing is also being used in the military to provide reliable computing resources in harsh combat environments. With rugged edge computing, soldiers can access the computing resources they need while on the move, even in the harshest conditions. This improves mission success rates and reduces the risk of equipment failure in the field.

Another area where edge computing is making a big impact is in smart manufacturing. By bringing compute and analytics closer to the production line, edge computing is improving efficiency, quality, and productivity in a variety of ways. For example, edge computing can enable predictive maintenance by continuously monitoring and analyzing equipment data in real-time. By predicting equipment failures before they occur, edge computing can save manufacturers time and money by avoiding downtime and reduce inventory costs by cutting down on the number of spare parts needed.

In addition to predictive maintenance, edge computing is also being used to optimize supply chains, improve product quality, and enhance worker safety in smart manufacturing. By providing real-time visibility into production processes and equipment performance, edge computing enables manufacturers to identify and address issues proactively, reducing downtime and improving product quality.

Finally, edge computing also offers benefits in terms of data privacy. By processing data at the edge rather than in the cloud, edge computing reduces the risk of data breaches and improves data security.

Conclusion

Emerging technologies are transforming the way we think about computing, and nowhere is this more evident than in the field of edge computing. By bringing compute and analytics closer to where data is generated, edge computing is improving performance, scalability, and data privacy for a variety of applications.

Rugged edge computing is particularly well-suited for use in industries such as oil and gas, mining, and military where computing resources must operate in harsh or remote environments. With rugged edge computing, these industries can benefit from the performance improvements and cost-savings of edge computing without having to worry about reliability.

Another area where edge computing is making a big impact is in smart manufacturing. By bringing compute and analytics closer to the production line, edge computing is improving efficiency, quality, and productivity in a variety of ways. By enabling predictive maintenance, optimizing supply chains, and improving worker safety, edge computing is helping manufacturers save time and money while improving product quality.

Overall, edge computing is a powerful technology that is transforming many industries. As more edge computing solutions become available, we can expect to see even more benefits in the years to come.